I-silicon ye-Monocrystalline ibhekisela ku-crystallization yezinto ezibonakalayo ze-silicon zibe ifomu elilodwa le-crystal, okwamanje isetshenziswa kabanzi izinto zokukhiqiza amandla e-photovoltaic, amaseli elanga e-monocrystalline silicon angobuchwepheshe obuvuthiwe kakhulu kumaseli elanga asekelwe ku-silicon, ngokuhlobene ne-polysilicon namaseli elanga e-amorphous silicon, ukusebenza kahle kwawo kokuguqulwa kwe-photoelectric kuphezulu kakhulu. Ukukhiqizwa kwamaseli e-silicon esebenza kahle kakhulu e-monocrystalline kusekelwe ezintweni ezisezingeni eliphakeme ze-silicon ye-monocrystalline kanye nobuchwepheshe bokucubungula obuvuthiwe.

Amaseli elanga e-Monocrystalline silicon asebenzisa izinduku ze-silicon ze-monocrystalline ngobumsulwa obufika ku-99.999% njengezinto zokusetshenziswa, okwandisa izindleko futhi okunzima ukuzisebenzisa ngezinga elikhulu. Ukuze ulondoloze izindleko, izidingo zezinto ezibonakalayo zokusetshenziswa kwamanje kwamaseli elanga e-monocrystalline silicon ziye zaxegiselwa, futhi ezinye zazo zisebenzisa izinto zekhanda nomsila ezicutshungulwe ngamadivayisi we-semiconductor kanye nokumosha izinto ze-silicon ze-monocrystalline, noma zenziwe zibe yi-monocrystalline silicon rods kumaseli elanga. Ubuchwepheshe be-monocrystalline silicon wafer milling buyindlela ephumelelayo yokunciphisa ukulahlekelwa ukukhanya nokuthuthukisa ukusebenza kahle kwebhethri.

Ukuze kuncishiswe izindleko zokukhiqiza, amaseli elanga nezinye izinhlelo zokusebenza ezisekelwe phansi zisebenzisa izinduku ze-silicon ze-solar-level monocrystalline, futhi izinkomba zokusebenza kwezinto ezibonakalayo zikhululekile. Abanye bangasebenzisa izinto zekhanda nomsila futhi bachithe izinto ze-silicon ze-monocrystalline ezicutshungulwa ngamadivayisi we-semiconductor ukwenza izinduku ze-silicon ze-monocrystalline zamaseli elanga. I-monocrystalline silicon rod isikwa ibe yizicucu, ngokuvamile cishe ngo-0.3 mm ubukhulu. Ngemuva kokupholisha, ukuhlanzwa nezinye izinqubo, isicwecwana se-silicon senziwa sibe isicwecwana se-silicon esisetshenziswayo ukuze sicutshungulwe.

Ukucubungula amaseli elanga, okokuqala kukho konke ku-silicon wafer doping kanye nokusabalalisa, i-doping evamile yokuthola amanani omkhondo we-boron, i-phosphorus, i-antimony nokunye. Ukusabalalisa kwenziwa esithandweni sokusabalalisa izinga lokushisa eliphezulu esenziwe ngamashubhu e-quartz. Lokhu kudala ukuhlangana kwe-P > N ku-wafer ye-silicon. Bese kusetshenziswa indlela yokuphrinta kwesikrini, ukunamathisela okuhle kwesiliva kuphrintwa ku-silicon chip ukwenza umugqa wegridi, futhi ngemva kokucwiliswa, kwenziwa i-electrode yangemuva, futhi ingaphezulu elinomugqa wegridi limbozwa ngomthombo wokubonisa ukuze kuvinjwe inani elikhulu lama-photons ukuthi lingabonakali ebusweni obushelelezi be-silicon chip.

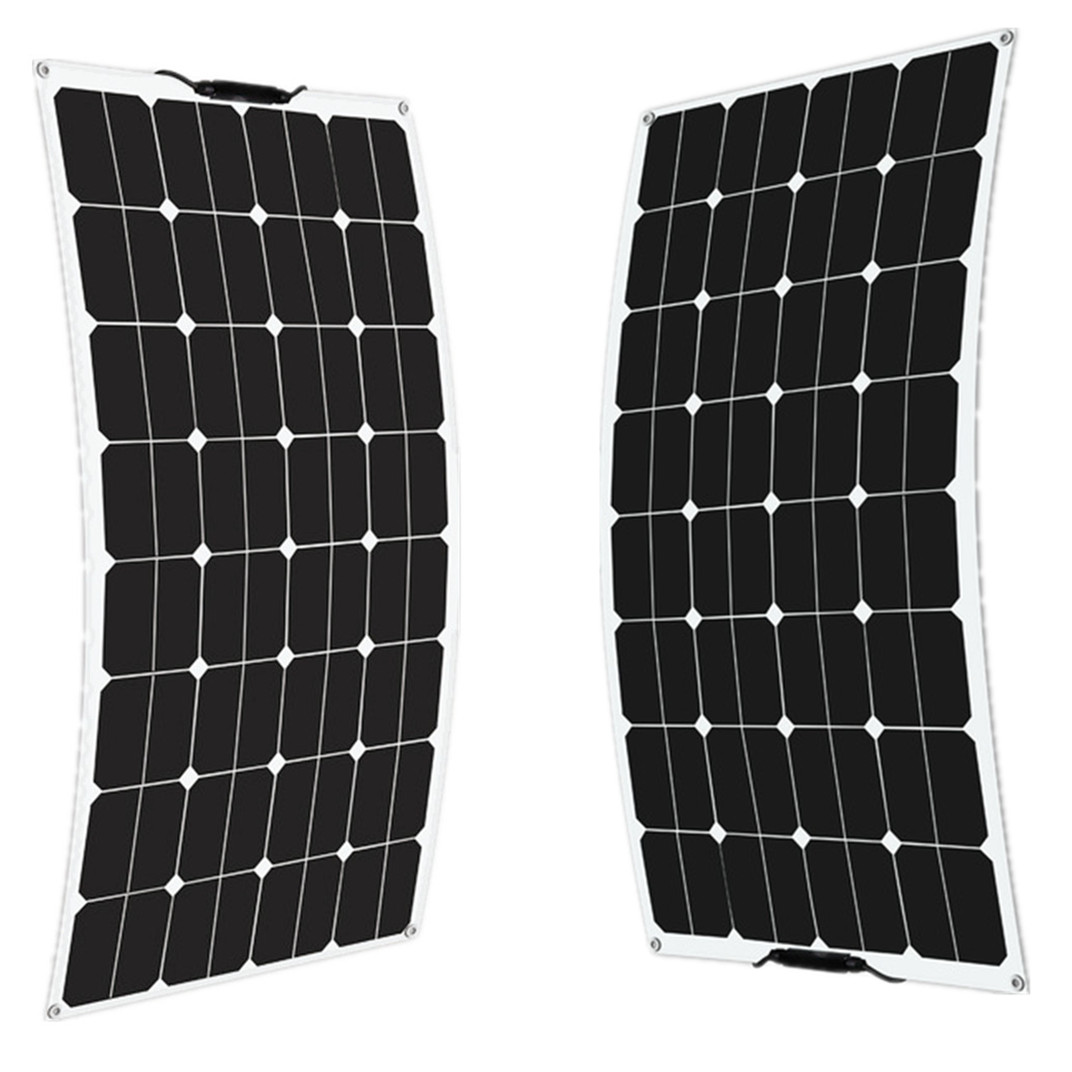

Ngakho, ishidi elilodwa le-monocrystalline silicon solar cell lenziwa. Ngemuva kokuhlolwa okungahleliwe, ucezu olulodwa lungahlanganiswa lube yimodyuli yeseli yelanga (iphaneli yelanga) ngokusho kwemininingwane edingekayo, futhi i-voltage ethile yokuphuma kanye namanje yenziwa ngochungechunge nezindlela ezifanayo. Ekugcineni, ifreyimu nezinto ezibonakalayo zisetshenziselwa i-encapsulation. Ngokusho komklamo wesistimu, umsebenzisi angakwazi ukuhlanganisa imojula yeseli yelanga ibe ngamasayizi ahlukahlukene ahlukahlukene we-solar cell array, eyaziwa nangokuthi i-solar cell array. Ukusebenza kahle kokuguqulwa kwe-photoelectric kwamaseli elanga e-monocrystalline silicon cishe ku-15%, futhi imiphumela yaselabhorethri ingaphezu kwama-20%.

Isikhathi sokuthumela: Sep-07-2023